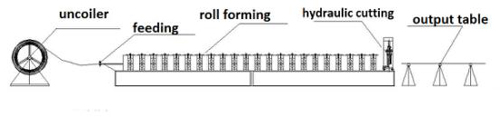

There has five parts to constitute a complete door frame roll forming machine. They are decoiler, feeder,roll forming machine, cutting part and run-out table.

To confirm the product, we use hydraulic cutter to confirm the product uniform and no burr.And we will make 22 rollers to make the product sharp and prefect.

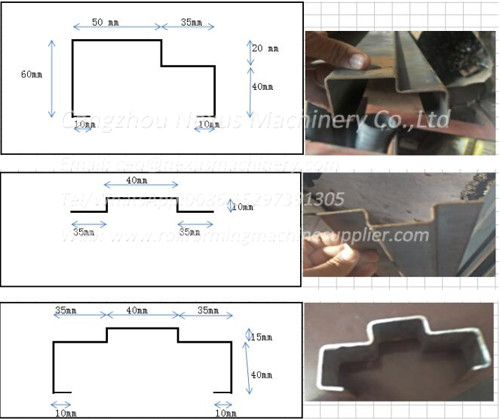

Customer drawing for your refer:

Working flow:

Uncoiler—Feeding—Roll forming—Hydraulic cutting—output table

Main Specification:

3T manual decoiler

1) Capacity: 3 ton

2) Loading width: MAX 300mm

3) Valid expanding range for coil inner diameter: 450-550mm

Main roll forming system with cutting

1) Main motor power: 7.5kw.

2) Hydraulic power: 3KW.

3) Structure: middle plate, 20mm thickness.

4) Shaft material: 45# steel

5) Shaft diameter:60mm.

6) Drive: Chain, 1.5inch.

7) Roll station: 22 groups

8) Roller material: 45# steel quenching treatment 58-62°.

9) Working speed: 5-10m/min.

10) Cutting: Hydraulic cutting after forming, Auto cutting when reach the set length.

11) Cutting blade: Cr12mov quenching treatment 58-62°.

12) Cutting tolerance: +/- 1.0mm,

13) Length Tolerance: ±1.5mm

14) Weight of machine: about 6.5ton

15) Size of machine: About7500×1200×1500mm L x W x H

16) Color of machine: depend on customer

18) Coder: Omron

19) Computer operating panel: touching screen

20) electric system brand: Delta or as you need